Hoover Dam

Concrete

Concrete consists of four ingredients-sand and crushed rock aggregate, water and Portland cement. These must be mixed in the proper proportions to yield strong concrete. Aggregate is perhaps the most important of the materials in the concrete because it makes up as much as three quarters of the Dam's mass. The aggregate must be clean and free of clays, salts and organic matter. A source of aggregate near the Dam was needed so that it would not have to be transported too far.

Bureau of Reclamation prospecting parties searched the desert around Black Canyon for months, looking for a good supply of aggregate. Eventually, an alluvial lens just over six miles upstream on the Arizona side of the river was chosen as the source. Here, floodwaters had been depositing stones for millions of years. Some of the rounded stones were as much as 12" in diameter and had been washed down from as far away as the Grand Canyon. The deposit covered more than 100 acres thirty to thirty-five feet deep.

A dragline was used to excavate the aggregate and load it into rail cars. The cars hauled the aggregate to a screening and washing plant on the Nevada side of the river at Hemenway Wash.

At the screening plant, four screening towers separated the aggregate into different sizes; fine, intermediate and coarse gravels, and cobbles 3-9" in diameter. Anything over 9" was run through a crusher and screened again. The separated gravel and cobbles were carried to the mixing plants by train.

The initial concrete required for the dam was

mixed in a river-level mixing plant which was located approximately 3/4 of a

mile upriver from the dam site This plant provided the concrete for the linings

in the diversion tunnels and for the lower levels of the dam. It went into

operation on March 3, 1932. The concrete was loaded into buckets which were

transported to the site initially by truck. Eventually, the concrete buckets

were transported by electric trains. For the first year of operation, nearly all

of the concrete produced at this plant, almost 400,000 cu .yd., went into the

linings of the diversion tunnels.

The initial concrete required for the dam was

mixed in a river-level mixing plant which was located approximately 3/4 of a

mile upriver from the dam site This plant provided the concrete for the linings

in the diversion tunnels and for the lower levels of the dam. It went into

operation on March 3, 1932. The concrete was loaded into buckets which were

transported to the site initially by truck. Eventually, the concrete buckets

were transported by electric trains. For the first year of operation, nearly all

of the concrete produced at this plant, almost 400,000 cu .yd., went into the

linings of the diversion tunnels.

In the tunnels, the concrete buckets were moved by a gantry crane which ran on rails from one end of the tunnel to the other.

The first concrete was placed into the dam on

June 6, 1933. The concrete was placed in the dam using 4 and 8 cu .yd. bottom

dump buckets. These buckets were lifted from the cars and lowered into place by

overhead cable ways. There were a total of nine of these cable ways used to

place the concrete. Five of the cable ways were connected to moveable towers,

which allowed them to be repositioned to work on different parts of the dam when

necessary.

The first concrete was placed into the dam on

June 6, 1933. The concrete was placed in the dam using 4 and 8 cu .yd. bottom

dump buckets. These buckets were lifted from the cars and lowered into place by

overhead cable ways. There were a total of nine of these cable ways used to

place the concrete. Five of the cable ways were connected to moveable towers,

which allowed them to be repositioned to work on different parts of the dam when

necessary.

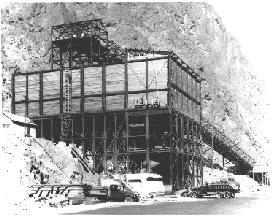

As the dam rose in height, a new concrete mixing plant was constructed on the canyon rim. Completely automated, the hi-mix plant measured ingredients, mixed and dispensed the concrete. It was capable of producing 24 cu .yd. of concrete every three and a half minutes. The hi-mix plant was used to produce all of the concrete placed in the dam above the 992 foot level.

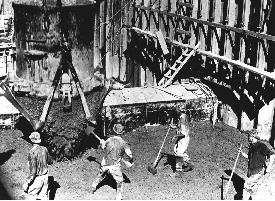

One of the problems was that in order to produce the strength concrete required, a very dry mix had to be used. There was very little time available to move the concrete from the mixing plant to the dam. If too much time was taken, the concrete would take its initial set still in the dump buckets and would have to be chipped out by hand. For this reason, the men who operated the cranes which moved the buckets into place were some of the highest paid workmen on the project, earning $1.25 per hour. As each bucket was dumped, seven puddlers used shovels and rubber-booted feet to distribute the concrete throughout the form and pneumatic vibrators to ensure there were no voids.

As the dam began to rise to fill the canyon, it grew it

fits and starts. Rather than being a single block of concrete, the dam was built

as a series of individual columns. Trapezoidal in shape, the columns rose in

five foot lifts. The reason that the dam was built in this fashion was to allow

the tremendous heat produced by the curing concrete to dissipate. Bureau of

Reclamation engineers calculated that if the dam were built in a single

continuous pour, the concrete would have gotten so hot that it would have taken

125 years for the concrete to cool to ambient temperatures. The resulting

stresses would have caused the dam to crack and crumble away.

As the dam began to rise to fill the canyon, it grew it

fits and starts. Rather than being a single block of concrete, the dam was built

as a series of individual columns. Trapezoidal in shape, the columns rose in

five foot lifts. The reason that the dam was built in this fashion was to allow

the tremendous heat produced by the curing concrete to dissipate. Bureau of

Reclamation engineers calculated that if the dam were built in a single

continuous pour, the concrete would have gotten so hot that it would have taken

125 years for the concrete to cool to ambient temperatures. The resulting

stresses would have caused the dam to crack and crumble away.

It was not enough to place small quantities of concrete in individual columns. Each form also contained cooling coils of 1" thin-walled steel pipe. When the concrete was first poured, river water was circulated through these pipes. Once the concrete had received a first initial cooling, chilled water from a refrigeration plant on the lower cofferdam was circulated through the coils to finish the cooling. As each block was cooled, the pipes of the cooling coils were cut off and pressure grouted at 300 pounds per square inch by pneumatic grout guns.

To prevent the hairline fissures between the blocks from weakening the dam, the upstream and downstream faces of each block were formed with vertical interlocking grooves; the faces turned toward the canyon walls with horizontal vertical grooves. When the concrete had cooled, grout was forced into these joints, bonding the entire structure into a monolithic whole.

Hoover Dam was the first man-made structure to exceed the masonry mass of the Great Pyramid of Giza. The dam contains enough concrete to pave a strip 16 feet wide and 8 inches thick from San Francisco to New York City. More than 5 million barrels of Portland cement and 4.5 million cubic yards of aggregate went into the dam. If all of the materials used in the dam were loaded onto a single train, as the engine entered the switch yards in Boulder City, the caboose would just be leaving Kansas City, MO. If the heat produced by the curing concrete could have been concentrated in a baking oven, it would have been sufficient to bake 500,000 loaves of bread per day for three years.

Source - U.S. Department of the Interior - Bureau of Reclamation