Glossary of Mining Terms

There are many terms and expressions unique to mining that characterize the field and identify the user of such terms as a “mining person.” The student of mining is thus advised to become familiar with all the terms used in mining . . . [Hartman and Mutmansky 2002:2]. Note: This glossary contains definitions of the mining terms used in this document, as well as a few additional terms that researchers are likely to encounter in archival documentation. Other useful glossaries and dictionaries containing exhaustive lists of mining terms are available and include Thrush’s (1968) A Dictionary of Mining, Mineral, and Related Terms, the American Geological Institute’s (1997) revision of that dictionary, and a periodically updated online glossary maintained by the Mining History Association (2011). These sources were consulted in compiling the definitions presented below; specific works are cited where text was drawn from those sources.Abandoned Mine

“An abandoned hard rock mine on or affecting public lands administered by the BLM, at which exploration, development, mining, reclamation, maintenance, and inspection of facilities and equipment, and other operations ceased as of January 1, 1981 . . . with no evidence demonstrating that the miner intends to resume mining” (U.S. Department of the Interior Bureau of Land Management [BLM] 2013:7).Adit

Horizontal or nearly horizontal mine passage beginning at the surface and extending underground, used for removing waste rock, ore, and/or water from a mine (Thrush 1968:12).Aggregate

Clastic material, such as sand or gravel.Amalgam/Amalgamation

An amalgam is an alloy of mercury and one or more other metals. Amalgamation is the production of an alloy in which mercury and another metal are united. The amalgamation process was used in gold and silver extraction. The term was also used to describe adjoining mining claims that were united for economic reasons (Thrush 1968:32), as in the Amalgamated Copper Company, at Greenwater near Death Valley Junction (Vredenburgh et al. 1981:251).Apex

Topmost extent of a vein. May be subsurface or outcropped at the surface.Arrastra

Also “arrastre” and “drag mill.” One of the simplest and least-expensive milling technologies; probably introduced to California mines by Sonoran miners (Kelly and Kelly 1983:85–86). The mill consists of a circular pavement of flat stones upon which broken ore is crushed. The crushing is accomplished by dragging stones around the circle; power is applied by various means. Both the pavement and drag stones become slickened in the process. As noted by Van Bueren (2004), the use of arrastras at mining sites often went unreported in official documentation.Assay

A test of mineral values by chemical process or smelting. Assayers determined the commercial value of ores.Assessment Work

The annual work or fees required by law to maintain rights to an unpatented mining claim or site.Backfill

Waste rock used to fill and support a stope, to prevent collapse.Ball Mill

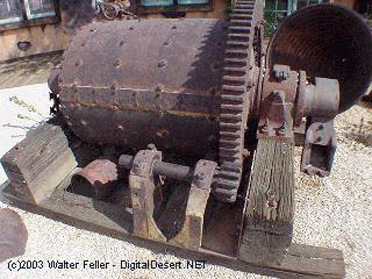

Crusher composed of a rotating cylinder or cone containing stone or metal balls that crush softer materials.Base Metal

Metallic ore, including copper, zinc, and lead, of lesser value than precious metals.Beneficiation

The concentration or enrichment of ore, including crushing, grinding, washing, flotation, and separation.Blasting Cap, Blasting-Cap Tin

Tubular shell loaded with detonating mixture. A fuse was inserted into the tube, and the shell was crimped onto the fuse before firing. Electric blasting caps were equipped with an electrical firing device in the cap and copper or iron wires extending from the cap. Standard sizes for mining applications were No. 6 and No. 8. Blasting caps were packaged in cylindrical or rectangular metal boxes (tins) and cushioned with heavy paper, felt, and sawdust. Boxes were embossed and/or lithographed with manufacturer information (Hercules Powder Company 1930; Martin 1991).Breast

See “face.”Button

A mass of lead containing gold and silver, produced during the scorification process of assaying. The hardened button is placed into a cupel, to separate the lead from the precious metals.Carbide Lamp

A lamp, typically affixed to a miner’s helmet or hardhat, in which calcium carbide and water are combined in the generation of acetylene gas as fuel for a flame (Fox 1985).Chilean Mill

Premotorized mill similar to an arrastra in its having an enclosed circular pavement or plate. Uses verticallypositioned rollers to crush ore. Also “roller mill.”Chlorination

Gold-recovery process in which auriferous ores are roasted to oxidize base metals, exposed to chorine gas, and treated with water to remove chloride of gold, from which gold is precipitated.Classifier

Separator to sort ore particles by weight and size. In ore dressing, a classifier separates the discharge from ball mills into what is ground fine enough and what which requires further crushing.Cobbing

Sorting valuable ore from waste rock by breaking with a hammer. A cobbing platform can sometimes be identified as a horizontal rock surface exhibiting scars from the process.Collar

The mouth or portal of a shaft, sometimes lined with wood as a support for subsurface lining or as a platform for aboveground structures.Country Rock

The rock adjacent to an ore deposit or through which an ore deposit runs (Osborn 1896:199).Cribbing/Cribbed Shaft

A shaft may be supported by cribbing, which is constructed by lining the open space with timbers and backfilling the space between the shaft walls and the crib.Crosscut

A horizontal underground mine tunnel that crosses the trend of the vein, ore, or structure of the rock in a mine (Wyman 1979:6).Crucible

A cup-shaped vessel made of refractory clay (fire clay), used in assaying for melting or calcining ores (Thrush 1968:283). Crucibles found at sites in California were typically made in western states or imported from Battersea, England. Sizes were numbered by capacity in grams (Fulton 1911:25; Furman 1902:59). Used crucibles frequently exhibit heat discoloration and sometimes contain glassy slag.Cupel

A small, thick, cylindrical saucer most commonly made of bone ash but also made of Portland cement. Used in assaying, to separate lead from gold and silver. In the process, the lead is both absorbed by the cupel and volatized, and silver and gold are left in the cupped surface of the cupel as a metallic bead (Fulton 1911:76).Daylight/Daylighted Stope

A stope or air vent that reaches the surface is said to be “daylighted.”Decline

A descending underground tunnel, not following the vein, used to access other parts of the mine.Deposit (see Mineral Deposit)

Dimension Stone

Cut or otherwise shaped rock for architectural- or engineering-construction applications.Double Jacking

Also “double hand-drilling.” Drilling method requiring two miners, one holding the drill bit and one wielding the two-handed hammer (usually weighing approximately 10 pounds [Thrush 1968:342]).Drift

A horizontal underground mine passage following the vein or structure of the rock.Drill Scar

The hole or partial hole left by a drill, usually after blasting has incompletely removed the surrounding rock.Drill Steel

Round or hexagonal drill bit used for boring into rock or ore.Face

The vertical wall at the end of a horizontal mine excavation; also “breast.”Foot Wall/Footwall

Rock stratum beneath a lode or vein; opposite of hanging wall.Gangue

Non-profitable minerals accompanying paying ore; sometimes includes minerals of lesser value than the targeted commodity.Glory Hole

A conical excavation, the top of which is at the surface and the bottom of which connects to underground haulage shafts and/or drifts. Ore is broken around the perimeter of the cone and is transported by gravity out the bottom of the cone, from where it can be hauled out of the mine. Glory holes are used where rich ore outcrops over underground workings convenient for haulage. A glory hole differs from an open-pit mine in that with the latter, materials must be removed from the top of an open pit that does not connect with underground workings.Grizzly

A stationary, sometimes portable, inclined screen used for sizing ore. Made of bars, perforated plate, or woven wire (Peele 1918:1651).Grubstake

Supplies and/or capital provided to a prospector to be used while searching for valuable minerals. The arrangement typically includes an agreement for the benefactor to share a portion of any discoveries made.Gyratory Crusher/Gyratory Breaker

A primary crushing mill that consists of a cone on a vertical spindle suspended in a larger cone. The interior cone crushes ore by eccentric gyration within the larger cone.Hanging Wall

The stratum above a vein or ore deposit; opposite of foot wall.Hard-Rock Mine

A mine excavated into hard rock—that is, material that can only be excavated by blasting. Excludes excavations into clay, sand, gravel, earth, and sedimentary rock. Sometimes “hardrock.”Headframe

Frame (timber or steel) on the surface above a shaft; supports hoisting apparatus.High-Grade Ore

Rich ore (Thrush 1968:542).Incline/Inclined Shaft

A shaft that deviates from the vertical, sometimes because it follows a vein.Jaw Crusher

Primary crusher mill used for initial reduction of ore from large rocks to a size that can be crushed further by a secondary mill. Jaw crushers trap ore between two plates, one of which oscillates against the other or both of which oscillate against each other (Thrush 1968:598).Level

Tunnels connecting on a common horizontal plane (Wyman 1979:6).Location/Locatable Minerals

Can refer to the act of delineating a mining claim or to the claim itself. Locatable minerals are any minerals “subject to acquisition” under the Mining Law of 1872 (BLM 2011a:3).Lode

A lode can be a single vein or a zone/belt of mineralized rock separate from adjacent non-mineral-bearing rock. Lode claims are filed on veins (lodes) of rock (in place) containing gold, silver, cinnabar, lead, tin, copper, or other valuable minerals (U.S. Department of Agriculture Forest Service 1983:5). Historical works sometimes refer to a lode as a “lead” (pronounced leed).Low-Grade Ore

Ore that is relatively poor in the metal for which it is mined (Thrush 1968:660).Mill

A reducing plant where ore is crushed and concentrated and where metals are recovered (Thrush 1968:706). Sometimes includes primary and secondary crushers for reducing ore into increasingly finer particles.Mill Site

Under the Mining Law of 1872, as amended, a claimant could file on non-mineral land for the purposes of processing ore in the development of a mineral claim.Mineral Deposit

“A concentration of minerals or elements of economic significance, in sufficient concentrations and quantities to warrant extraction at reasonable cost” (BLM 1991b:2).Mineral Entry

A mining claim filed on public land.Mining Claim

A lode claim relates to veins or lodes “having well-defined boundaries and also [including] other rock inplace bearing valuable mineral deposits. Examples include quartz or other veins bearing gold or other metallic mineral deposits and large volume, but low-grade disseminated metallic deposits. . . . Lode claims are usually located as parallelograms with the side lines parallel to the vein or lode. . . ” (BLM 2011a:7–8).Open Pit

Metalliferous lode deposits are sometimes accessed by open-pit-mining methods, which have become increasingly common during the past four decades, because technology and mineral values have made the mining of lower-grade ores profitable. Gold/silver, iron, and copper are most frequently mined using this method. Similar to quarrying, open-pit-mine workings are entirely open to the surface. Because they do not result in underground workings of lode deposits, open-pit mines are not considered in this study. Open pits should not be confused with glory holes, daylighted stopes, or collapsed stopes.Ore Bin

A wooden or concrete box used to contain ore. Usually positioned above a mill or at the side of a road where ore can be loaded onto wagons, trucks, or a train for transport. The top of the bin is generally open so that ore can be dumped into it from wheelbarrows, ore cars, or conveyors. The floor of the bin is generally sloped toward a gate at the front, by which the flow of ore from the bin can be controlled.Ore Car

A wheeled bin used to transport ore, waste rock, and/or tools through and from a horizontal mine passage. Frequently erroneously referred to as “ore cart.”Ore Dressing/Mineral Dressing

Beneficiation. The process of “mechanically separating and saving valuable minerals from the valueless material of an ore” or “mechanically separating two or more minerals, which combined have little value, into two or more products, each of increased value” (Richards and Locke 1940:1).Patent/Patented Claim

A mining claim or mill site is patented when the federal government has conveyed title to the claimant. Upon title conveyance, the claim essentially becomes private land, and the patentee has legal title to the locatable minerals and activities on the surface (BLM 2011a:27).Placer

Particles of metal that have been freed from ore-bearing deposits through exposure to weathering.Portal

The entrance to a horizontal or nearly horizontal mine tunnel.Prospect

A location where valuable minerals have been sought by exploration.Pulp

Ground ore combined with water.Raise

Underground passage driven from one level up to the next (Wyman 1979:6).Roller Mill

See “Chilean Mill.”Scorification, Scorifier

Scorification is the assay process by which gold or silver is dissolved through heat into a button of molten lead. The process is accomplished in a scorifier, a shallow vessel made of refractory clay (fire clay). Most scorifiers used in California mines were produced in western states or imported from Battersea, England. They are designated by the measurement in inches of their exterior diameters (Fulton 1911:26; Furman 1902:61).Shaft

A vertical or inclined mine excavation used for recovering or accessing ore; for bringing water, ore, supplies, or personnel up from underground workings; or for ventilation.Single Jacking

Also “single hand-drilling.” Drilling method performed by a single worker holding the drill steel in one hand and a small hammer (usually 4 pounds or less [Thrush 1968:1016]) in the other.Slimes

Ore ground to such a fine consistency that the particles can be suspended in water.Square-Set Timbering

A method of timbering used to support a stope; consists of vertical and horizontal members meeting at 90° angles. The square-set timbering method was devised for use in the mines of Comstock, Nevada, where veins and ore bodies were of very large size (Storms 1894:38–50).Stamp Mill

A type of mill that crushes ore on the principle of a mortar and pestle, with the pestle repeatedly raised and dropped by force of gravity onto ore in a trough. The stamps, which are usually built in multiple batteries of five, can also be single-, double-, or five-stamp arrangements.Stope

A pocket from which ore is removed, usually excavated as an enlargement of a drift or crosscut (Wyman 1979:6).Stull

Post used in an inclined vein; usually the bottom of the post is set in a notch, and the top of the post has a cap between it and the hanging wall (Crane 1908:451).Tailings

The debris from ore-beneficiation activities after valuable minerals have been removed to the extent possible. The term is frequently misused to describe waste-rock and low-grade-ore dumps.Timbering

Posts and beams supporting portals and underground mine workings. Can be engineered (e.g., square-set method) or informal and expedient.Tunnel

Horizontal or nearly horizontal mine passage running completely through a hill or mountain, with portals on each side (Thrush 1968:12, 1173).Vein

A zone of mineralized rock that is clearly separated from the surrounding rock (Thrush 1968:1198).Waste Rock/Waste-Rock Dump

Rock or ore that has been removed from a mine but is of insufficient value to be profitable if treated; it is deposited out of the way without entering the milling process. The term is frequently misused to describe tailings.Whim

Also “whimsey”; a hoisting apparatus to raise water or ore from a shaft by winding a cable around a drum, using horsepower or a steam engine.Winze

A downward-trending tunnel driven from a higher level, sometimes following an ore body (Wyman 1979:6). --Mining in the Southern California Deserts:

A Historic Context Statement and Research Design

Appendix A

Karen K. Swope and Carrie J. Gregory