Stamp Mill

A stamp mill operates by crushing material (usually ore) to extract the valuable metals or minerals contained within. Here's a simplified overview of its operation:Ore Feeding: Ore is fed into the stamp mill's hopper, a large container that holds the ore before it is processed. The hopper releases the ore into the mill at a controlled rate.

Crushing Mechanism: The core feature of a stamp mill is a series of heavy stamps (or hammers) arranged in a frame. These stamps are lifted by a camshaft or a powered mechanism and then dropped onto the ore and water mixture below. The stamps are typically made of heavy metal or steel and are often arranged in a vertical framework called a stamp battery, where several stamps can operate in sequence.

Pulverization: As the stamps repeatedly rise and fall, they crush the ore against a hard surface, usually a flat, heavy metal plate or a bed of hard rock. The process of dropping the heavy stamps on the ore breaks it into smaller pieces, effectively pulverizing the rock and releasing the valuable minerals from the surrounding material.

Water Addition: Water is usually added to the ore as it is being crushed. The addition of water helps to lubricate the crushing process, making it easier for the ore to be broken down. It also aids in the subsequent separation of valuable minerals from the crushed rock.

Separation of Materials: After the ore has been crushed, the mixture of water, pulverized ore, and any valuable minerals is passed over a series of tables or screens. The heavy minerals (like gold) settle to the bottom and are collected for further processing, while the lighter waste material (gangue) is washed away.

Extraction of Metals: The collected minerals might undergo additional processing steps, such as amalgamation (for gold and silver), where mercury is used to amalgamate the precious metals. The amalgam is then heated, vaporizing the mercury (which is captured and reused) and leaving the purified metal behind.

Refining: The extracted metals are often refined further to increase their purity and value.

Stamp mills were widely used in mining operations during the 19th and early 20th centuries, especially for precious metals like gold and silver. While the basic principle of operation has remained the same, modern mineral processing techniques have largely replaced stamp mills due to their relatively low efficiency and the high labor costs associated with their operation.

Parts of a Stamp Mill

The stamp mill is a complex machine that crushes ore to extract valuable metals. Its main components include:Stamps: These are the heavy iron or steel tools that crush the ore. Each stamp consists of a shaft (stem) with a heavy metal shoe attached to the bottom. The stamps are lifted and dropped onto the ore by a mechanical process.

Camshaft: This is the mechanism that lifts the stamps. The camshaft is powered by a water wheel, steam engine, or electrical power, and it turns, lifting the stamps by engaging cams (or lifts) against the stems of the stamps.

Tappets: Attached to the stamp stem, tappets interact with the rotating cams on the camshaft. As the cam rotates, it hits the tappet, lifting the stamp.

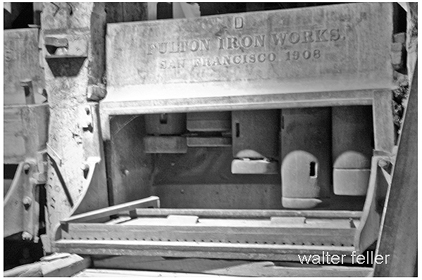

Battery Box (Mortar Box): This is the structure that houses the stamps. It is a heavy, steel or iron box where the ore is crushed. The interior is often lined with replaceable steel or hardened rubber liners to withstand the impact of the stamps.

Grizzly: Before the ore reaches the battery box, it is often sized on a grizzly, a metal grate that screens out oversized rocks. The smaller ore pieces fall through the grizzly into the ore bin or directly into the battery box, while larger rocks are broken up or discarded.

Ore Feeder: This device controls the flow of ore into the stamp mill. It ensures that the ore is fed into the mill at a steady rate for uniform crushing.

Amalgamation Plate: This is a copper plate coated with mercury. It is positioned at the discharge area of the stamp mill to capture fine gold particles from the crushed ore-water slurry. The gold amalgamates (binds) with the mercury and can then be separated and purified.

Discharge Screens: These screens are placed at the exit of the battery box. They allow the finely crushed ore and water slurry to pass through while retaining the larger pieces for further crushing.

Water Supply: Water is a crucial part of the stamp milling process for both ore processing and the amalgamation process. A consistent water supply is needed to mix with the ore and to facilitate the separation of the metals.

Pulleys and Belts: In some designs, especially those powered by steam engines or electric motors, pulleys and belts transfer power from the engine to the camshaft.

Tailings Area: After the ore is processed, the waste material (tailings) is discharged to a designated area. This material is often processed further to extract any remaining valuable metals.

These parts work together in a coordinated manner to crush the ore and extract valuable metals efficiently. The design of stamp mills can vary depending on the mining region and the type of ore being processed.

Also see:

The Lost Horse Mine

The next year he found a steam-powered, ten-stamp mill somewhere near the Colorado River and had it dismantled and hauled to the mine site. ...

Keane Wonder Mine - Death Valley National Park

In 1906, L.L. Patrick got the bond for the mine, and he announced plans to erect a 20 stamp mill at the foot of the Funeral Range. When his bond expired, ...

Bodie, CA

Gold bullion from the town's nine stamp mills was shipped to Carson City, Nevada accompanied by armed guards. Once the bullion reached Carson City, ...

Moorten's Mill

"Cactus" Slim Moorten built a 5-stamp mill here in 1934 to process gold ore from 3 claims he had in the Cottonwood Spring area. Abandoned in 1939 little ...

Calico Ghost Town History

At first the ore from the Silver King Mine was hauled to Oro Grande, 40 miles away, but in 1882 a ten-stamp mill was erected beside the Mojave River at ...

Garlock Ghost Town

In 1894 Eugene Garlock of Tehachapi moved in an eight stamp mill. Miners would talk of going down to "the Garlock mill," "down to the Garlock," and finally ...

Lucky Baldwin/ Gold Mountain Mine, Big Bear - San Bernardino

...San Francisco multimillionaire, Elias J. "Lucky" Baldwin started a "gold rush" in 1874 when he constructed a large 40 stamp mill at the base of "Gold ...

Winona Mill - Joshua Tree National Park, Colorado Desert

...winona stamp mill photos - joshua tree national park, mojave desert. ... Winona Mill Cottonwood Spring Colorado Desert Mastodon Peak ...

Camshaft (Randsburg)

Stamper stems (Randsburg)

Stamp battery (Standard Mill, Bodie)

Wall Street Mill, Joshua Tree National Park

Amalgamation table, Standard Mill, Bodie

Shaker table, Wall Street Mill